•Limited options for an effective well managed solution

• Limited land to allocate waste

• High emission levels of carbon dioxide into the atmosphere producing a greenhouse effect

• Long-term effects include signs of mutation in animals, cancer and other diseases in humans

• Excavation of land specifically for deposition of wastes are common, often accompanied by burning of wastes to reduce volume, a practice determined to be a contributor to degraded air quality in urban areas

•Toxins in our waterways, air, cities and green spaces, and the contamination of many natural resources

Currently, about 2.01 billion

metric tons of municipal solid waste (MSW) are produced

annually worldwide. The World Bank estimates overall waste

generation will increase to 3.40 billion metric tons by 2050.

An estimated 13.5% of today's waste is recycled and 5.5% is composted

-World Bank-Sep 23, 2018

Reports estimate that between one-third and 40% of waste generated worldwide is not managed properly and instead

dumped or openly burned

Our mission is simple,

to offset the devastating effect of waste on the planet in addition to providing much needed energy. The Smart Waste Converter

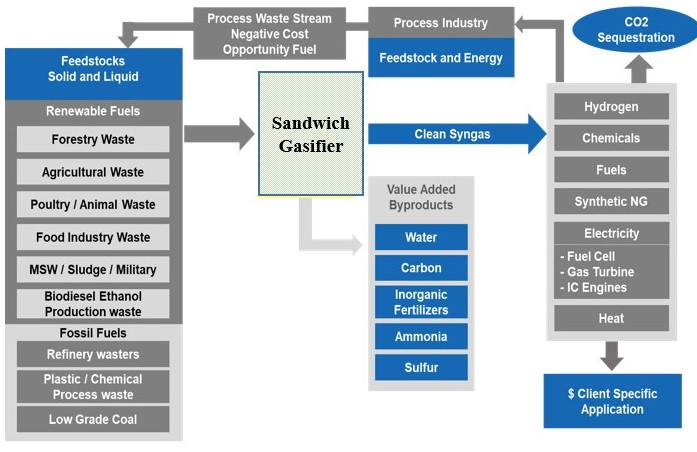

Smart Waste Converters use gasification to transform complex materials into a synthetic gas (syngas) that can be used as fuel to run electrical

generators or it can be recombined to produce liquid fuels for the client: (e.g., methanol, ethanol,

... gasoline, diesel, JP-8).

The Smart Waste Converter's unique design

that enables it to completely gasify materials regardless of composition. (e.g., wet vs. dry; high vs. low energy).

Because the Smart Waste Converter can convert virtually

all of the feedstock material into clean syngas, in an extremely efficient way, it leaves behind virtually no unconverted char, tar,

or particulates that might otherwise foul the interior structures of less capable systems.

This is not your grandfather’s gasifier…

What makes it different?

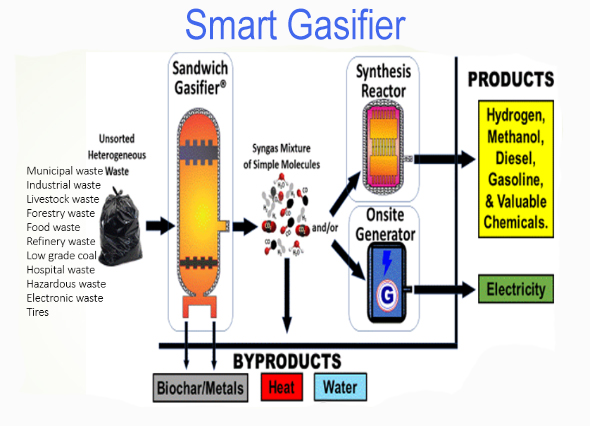

The Sandwich Gasifier is named after its unique reaction zone layers which control heat to

complete gasification of materials of variable compositions (e.g., wet vs. dry; high vs. low energy).

Smart Waste Converters use a Sandwich Gasifier to vaporize complex waste materials into

a gas composed of simple molecules that can be used as fuel (synthetic gas = syngas) Syngas can either fuel

electrical generators, turbines or recombined into liquid fuels (i.e., methanol, gasoline, diesel, jet fuel,

chemical precursors, and other products). Lower capital/operating costs and higher productivity of Sandwich

Gasifiers enhance profits and improve sustainability of client operations.

Competitive Advantages of the Sandwich Gasifier Conventional technologies can’t

maintain adequate heat

in their reduction zones so syngas production diminishes as internal temperatures diminish. Their dirty

syngas impairs their ability to continue operating.

Sandwich Gasifiers maintain reduction zone temperatures using heat provided by additional oxidation to prevent dead zones where material is no longer

converted into clean syngas.

Sandwich Gasifiers tolerate variable feedstock size, moisture, and energy contents. This enables

them to convert materials into clean, acid-free syngas with near-zero emissions and clean ash.

The waste disposal issues faced by companies, communities, military, and others are driving forces for clients considering Smart Waste Converters. Among the first inquiries of a client is how their investment will perform if they obtain the technology. During project development, preliminary waste and site-specific revenue generation potential assessments of revenues from 1) tipping fees (or reduced disposal costs), 2) the sale of the heat, 3) power, 4) liquid fuels produced from system operation, or 5) other byproducts such as clean ash, recovered water, recovered metals, etc.

Lower Capital Cost

Small, (i.e., low cost) real estate footprint. Sandwich gasifiers reduce the need for pre- and post-treatment component systems, thus reducing capital costs. Small scale – 10, 25 ton/day systems are economically viable - allowing phased expansion via modularity which simplifies operating cash flows. Biochar made by sandwich gasifiers preserve value of farmland by preventing use of low-quality biochar made using inadequate production processes that form and can leave behind dioxins and other contaminants such as pyrolysis, torrefaction, or conventional gasification.

Little or no pretreatment is needed for many feedstocks. Distributed processing allows waste conversion to be closer to waste/biomass production sites – reducing transportation costs (and transportation-associated carbon emissions). Modular processing simplifies handling of highly variable feedstock availability since individual units can be shut down for maintenance/modification while all other units continue working. Unique design maintains more uniform temperatures in the gasifier which helps preserve the life of the system while minimizing residual tar or char and maximizing syngas production. No catalyst or other expensive additives are needed to start or maintain the process. Significant reduction in costs for disposal or conversion of harmful emissions/by-products due to near zero emission of particulates, liquids, or gases needing cleaning or scrubbing. Systems readily comply with stringent environmental regulations with full transparency.

10-100s Tons/Day

Valuable Clean Energy

Rapid Return based on quality of input and local market for output...